In industrial piping insulation, the choice of material can determine the lifespan of an entire infrastructure. For procurement managers and thermal engineers, Foam Glass Tube Shells have emerged as the gold standard for extreme environments. Known for their cellular structure and inorganic composition, these shells solve the most persistent challenges in petrochemical, power generation, and LNG processing.

Understanding the Cellular Structure Advantage

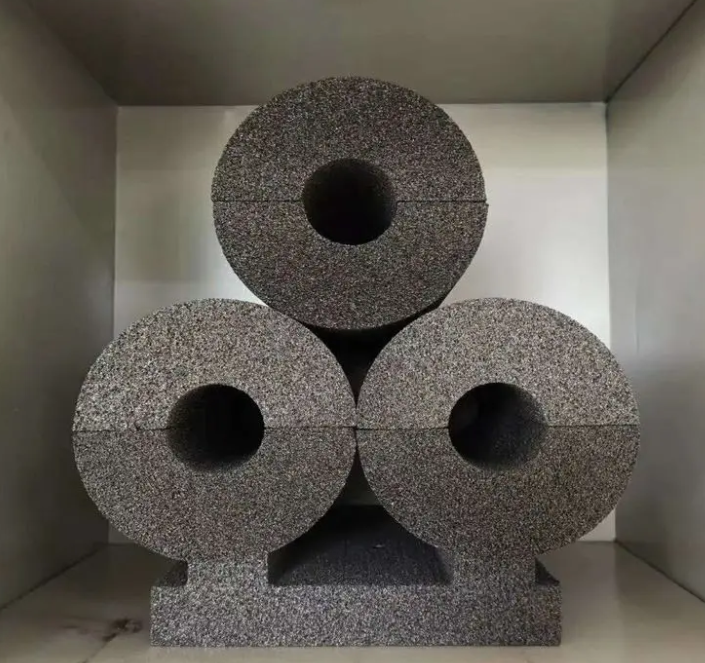

Foam glass is a lightweight, rigid material composed of millions of completely sealed glass cells. Unlike fibrous or open-cell insulation, this structure is inherently impermeable. When fabricated into a tube shell format, it provides a 360-degree moisture barrier that is critical for preventing Corrosion Under Insulation (CUI)—one of the most costly defects in industrial piping.

Critical Technical Challenges in Piping Insulation

Based on field performance data from thermal energy projects, three primary issues often compromise standard insulation materials:

-

Moisture Absorption: Most materials lose their thermal resistance ($R$-value) when exposed to humidity. Foam glass maintains a 0% water absorption rate, ensuring consistent performance.

-

Dimensional Instability: In extreme temperature fluctuations, insulation can shrink or crack. Foam glass has a low coefficient of thermal expansion, matching closely with steel pipes.

-

Combustibility: In high-risk environments, fire safety is paramount. Foam glass is strictly Class A1 Non-combustible.

Industry Standard: According to ASTM C552, foam glass is the only insulation material that effectively combines high compressive strength with absolute vapor impermeability for operating temperatures ranging from -196°C to +400°C.

Comparative Data: Foam Glass vs. Conventional Insulation

To assist technical buyers in material selection, the following table compares the performance benchmarks of the Huaneng Foam Glass Series against standard polyurethane and mineral wool:

Technical Property Polyurethane (PU) Mineral Wool Operating Temp Range -100°C to +100°C Up to +600°C Water Vapor Permeability Moderate High Fire Resistance Class B (Combustible) Class A1 Compressive Strength Low Very Low High (≥0.7 MPa) Service Life 5-10 Years 8-12 Years 20+ Years Key Benefits for B2B Procurement and Engineering

Investing in high-quality Foam Glass Tube Shells offers measurable operational ROI:

CUI Prevention: By blocking all moisture ingress, it eliminates the chemical environment required for steel pipe corrosion, drastically reducing maintenance costs.

Chemical Resistance: Resistant to most acids and industrial solvents, making it ideal for harsh chemical processing plants.

Rodent and Bacteria Proof: As an inorganic material, it does not support the growth of mold or attract pests, ensuring hygienic conditions in food and pharma sectors.

Easy Installation: Precision-cut shells fit snugly over standard pipe diameters (DIN/ASTM), reducing labor time and ensuring a gap-free thermal seal.

Conclusion: The Sustainable Choice for Industrial Insulation

For modern industrial projects, “cheap” insulation often leads to expensive failures. The Foam Glass Tube Shell represents a long-term engineering solution that balances thermal efficiency with structural durability. By selecting a material that does not degrade, leak, or burn, companies can ensure the safety and efficiency of their piping systems for decades.

Get a Technical Consultation Today

Are you designing a cryogenic system or upgrading a high-temperature steam line?

View Product Specs: Foam Glass Tube Shell Catalog

Request a Quote: Contact our technical team for custom thickness and diameter requirements.

Global Shipping: Certified packaging and logistics for international project sites.

Post time: Feb-06-2026